Mod Details

PremiumYes Difficulty

Mod ID1266

Creditevilution

For

Mod ID1266

Creditevilution

For

Linkhttps://www.evilution.co.uk/mod/brake-pipe-replacement.htm Copy to Clipboard

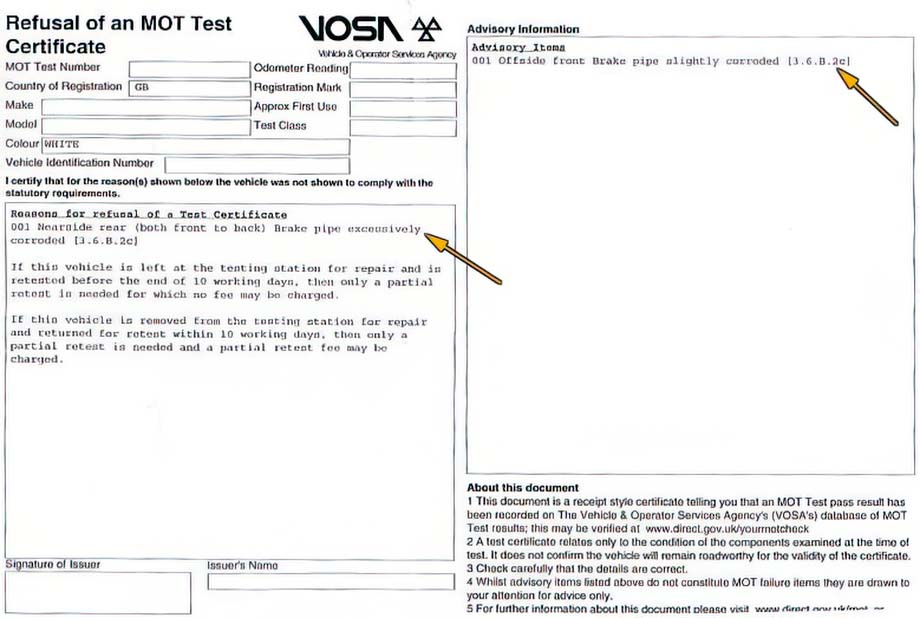

Linkhttps://www.evilution.co.uk/mod/brake-pipe-replacement.htm Copy to ClipboardIt’s a fairly common failure or advisory on an MOT.

Normally it’s just the tester panicking and the corrosion can be sanded off and the pipes painted. However, sometimes the pipes are just too far gone and the corrosion causes a hole.

You have 2 options.

Expensive but easy = go to smart and buy the pre-formed pipes and fit them.

Cheap but extra work = make your own brake pipes.

Considering the pre-formed pipes are expensive and making your own is 1/3rd of the price, let’s make them.

Remove The Old Pipe

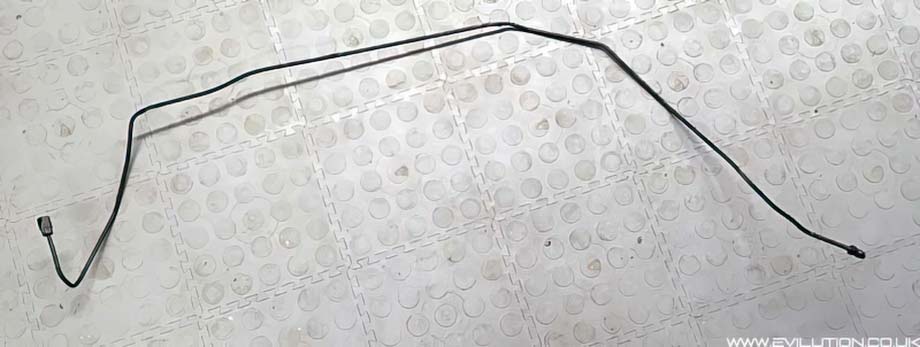

Obviously we need the old one off, not just to make room though. We need it for a template. Unbolt it from each end. I think you are old enough to work out what size spanners you need.

The pipes are clipped to the chassis along the route. Unclip the pipes.

On the rear, the pipes connect to hoses to allow for the suspension movement.

You just have to pull the clip out…

…then you can throw a spanner on each side and disconnect the 2.

You now have your template to copy.

Pre-formed pipes are expensive but a coil of unformed brake pipe is fairly cheap. This kit cost £15 on eBay.

It’s 3/16″ (4.75mm) copper nickel, also known as kunifer, cunifer or cupronickel. It doesn’t work harden like normal copper pipes but it is slightly harder to form. Most importantly though, it’s far more resistant to corrosion.

In the kit I bought, I got the 10mm male connections…

…and the 10mm female connections