Mod Details

PremiumNo Difficulty

Mod ID1791

Creditevilution

For

Mod ID1791

Creditevilution

For Linkhttps://www.evilution.co.uk/mod/451-dump-valve.htm Copy to Clipboard

PartsBuy here

Linkhttps://www.evilution.co.uk/mod/451-dump-valve.htm Copy to Clipboard

PartsBuy hereBecause I wanted a dump valve on my 451 turbo, we spent thousands having having custom silicone pipes made by Forge Motorsport. They cost us an absolute shitload each so we stuck the rest on SmartMods just in case anyone else wants to do the same. This is the T piece. It’s also available in blue. Click the banner at the bottom of the page.

You will need to obtain a dump valve. I would recommend one with a side exit vacuum nipple because the engine bay doesn’t have a load of space.

I also recommend Forge DVs specially designed for the smart as it has a restricted port size to match the turbo outlet.

You will have to contact Forge Motorsport about this custom order because they don’t sell the smart DV with a side vacuum nipple.

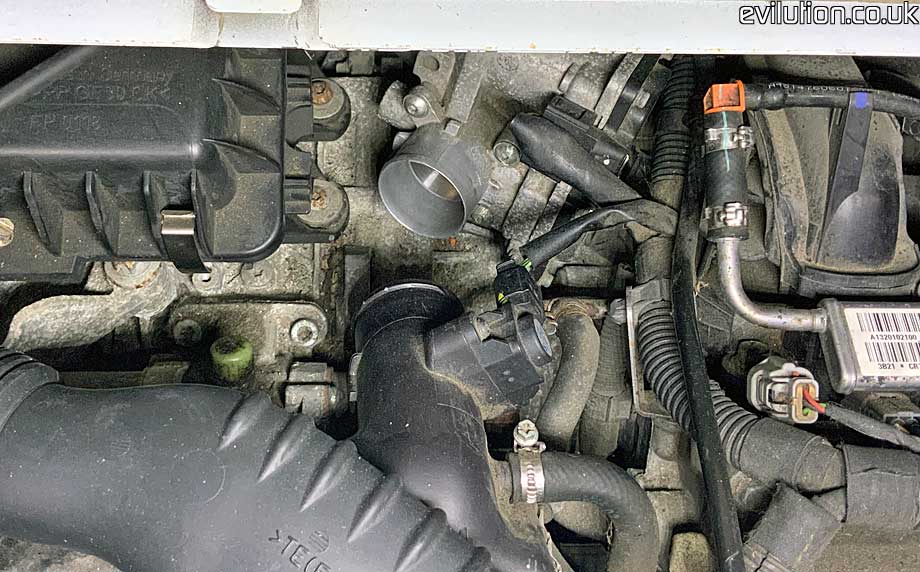

Take off the old pipe that goes to the throttle body and then remove the throttle body by taking out the Torx 25 screws all around and disconnect the electrical connector.

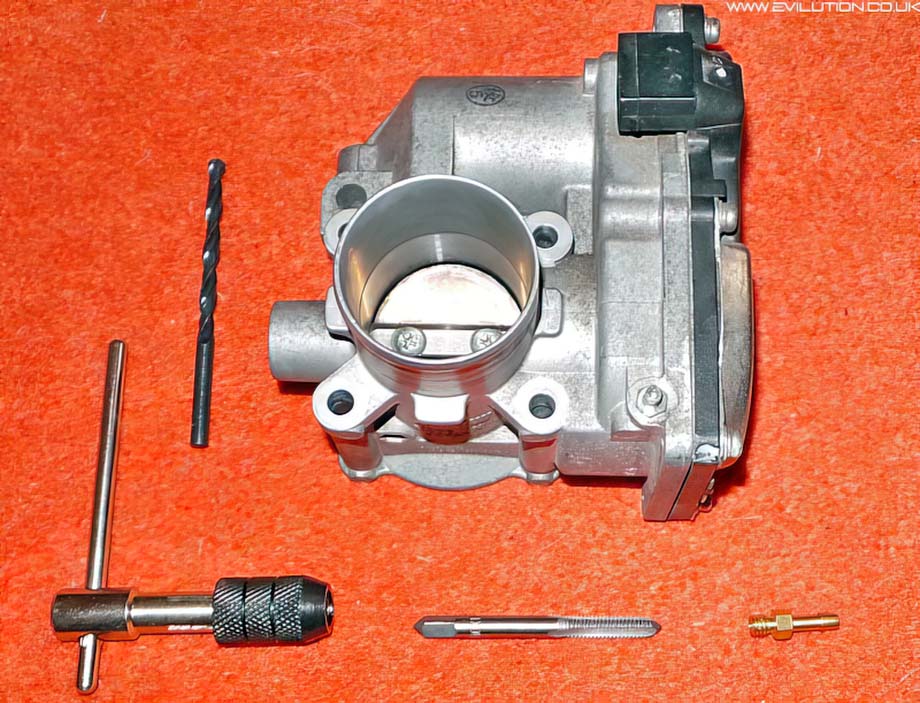

You need to create a port to connect a vacuum line behind the throttle body. For the sake of time, I just drilled, tapped and glued a barbed hose connector into the back of the throttle body.

A 5mm drill bit, a 6mm tap, tap wrench, a 6mm barbed hose connector and some kind of sealant.

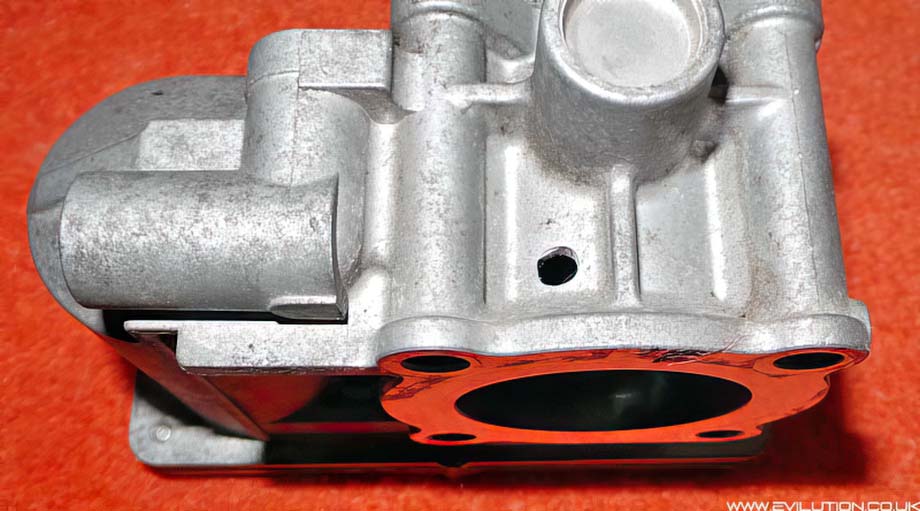

You will have to decide the best place for the pipe to emerge. There seems to be more room out the left side. I took the 5mm drill bit and drilled a hole through the throttle body. The hole emerges behind the plenum.

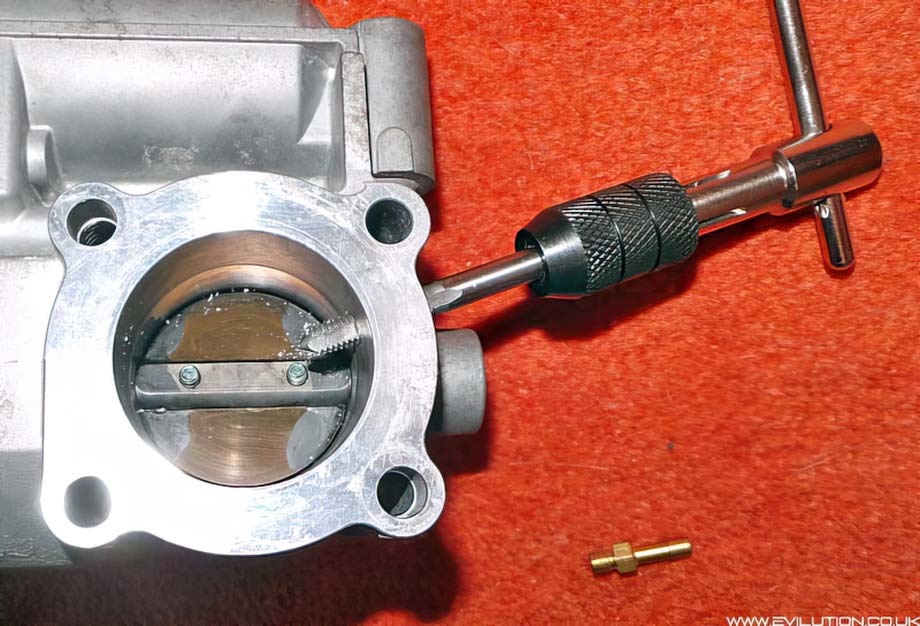

I used a 6mm tap that matched the thread pitch of the 6mm barbed hose connector that I had bought. Screwing in the tap will thread the soft aluminium so the barbed hose connector can be screwed in later.

The thread must be sealed as best as possible. You can try threadlock fluid, glue, chemical metal or PTFE tape. I used threadlock which worked ok but did leak very slightly which isn’t a problem.

I screwed the barbed connector in tightly and allowed the threadlock liquid to set.

The excess thread doesn’t foul any moving parts so you can leave it, add an extra nut or grind it away.

I decided to leave the thread and apply some superglue gel to the inside to attempt a perfect seal. Give the throttle body a good clean out to remove any metal swarf to stop it getting in the engine.

Refit the throttle body connect the vacuum hose to the new barbed hose connector. Fit the hose clamps to the new silicone T piece…

…and fit then tighten the hose clamps.

Make sure it’s angled nicely and double check the clamps are tight.

Fit the side nipple DV and tighten the clamp down.

Connect up the vacuum line…

…and you are done.

Now you can see why the DV required a side exit vacuum nipple. If you fit a standard top exit DV, the vacuum hose will kink and rub and nothing will function correctly.

You are probably best off going for the weakest spring available but you may need to fit an uprated spring depending on the boost of your car.

Movie Time

When I was making sure the idea worked, I cobbled together some parts and took a video.

Then when I was happy and we spent way too much getting the pipes made, I took another video.